|

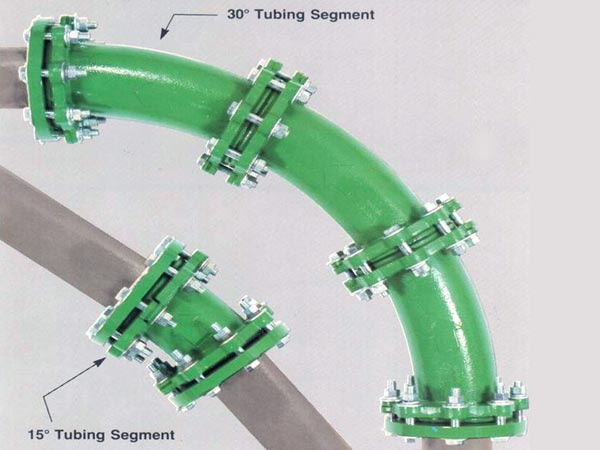

"Curves in layout"

Reduces materials plugging

The 15o, 30o, 45o and 100o segmented tubing bend represents an advanced design to reduce conveying line shock and to handle difficult materials, which tend to compact and plug up when changing directions in the conveying line. Its special design provides a pressure relief across the entire length of the tubing bends resulting in easier conveying of most any material. In our standard equipments & design range bends provided are of converging - diverging type i.e. wherein bend area decreased (thus thickness increases) at the segment outlet, which keeps the material floating and unsettled thus eliminating the chances of choking in the bend section Hardness of bend ranges from 350 to 400 BHN.

Easier to install

The segments are easier to install and stock than heavier one- piece tubing bends which are more difficult to maneuver than the smaller lighter weight segments. Also the basic design makes installation much easier as the segments cannot be misaligned when assembled and it is substantially more forgiving when connecting to adjacent conveying lines, which are not at perfect angles.